who we are

Allied Hori At A Glance

5600

5

30

200 +

Your End-to-End Manufacturing Services

Our services encompass the entire production process, including Product Design, Tooling Development & Fabrication, PCBA development & production, Plastic Injection Moulding and Assembly.

Equipped with a comprehensive tool room setup, our team of skilled designers and manufacturing personnel are position to provide cost-effective custom mould making services.

We possess a diverse range of Injection Machines, ranging from 30T to 350T, enabling us to produce a wide variety of parts.

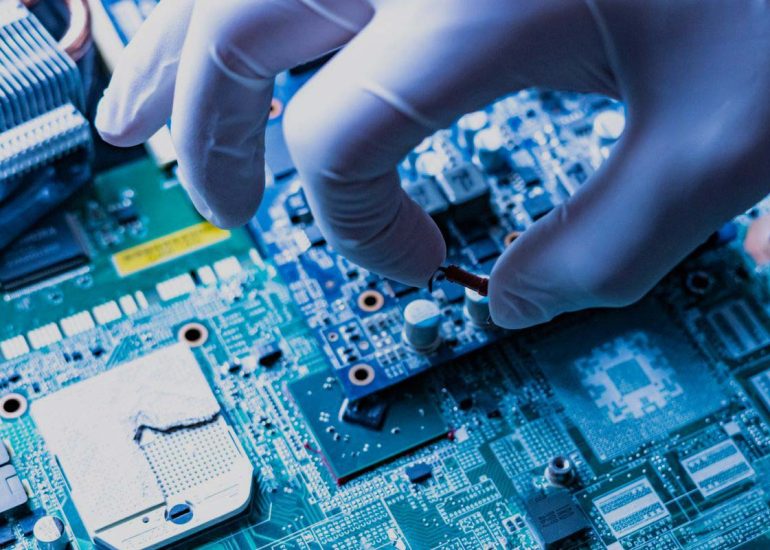

Our offerings extend to encompass value-added services, including PCB Assembly Design and Manufacturing.

Our state-of-the-art automated spray painting line is specifically designed to ensure consistent, high-quality finishing.

Experience seamless end-to-end production for efficient semi-assemblies and complete assemblies – turnkey Electronic Manufacturing Services, elevating your electronic projects.

Why choose us

Your Comprehensive End-to-End Production Partner

Complete end to end facilities and expertise

Systematic Manufacturing Process

Process Specialists

30

Years Of Experiences

What we do for you!

Advanced Moulding Technology

- Precise Parameter Control

- Enhanced Product Quality

- Improved Dimensional Accuracy

- Enhanced Process Stability

- Efficient Cycle Times

- Streamlined Production

Applications

Industries We Serve

Our Clients

Uncompromising Quality Standards

Your Sourcing Needs Start with Allied Hori!

Let's get started.